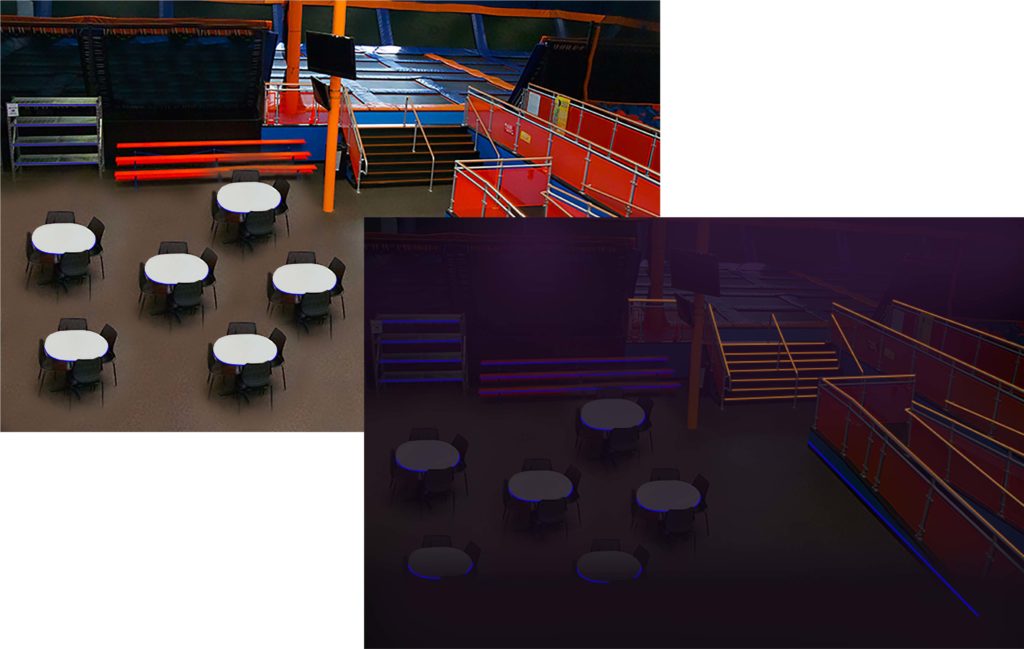

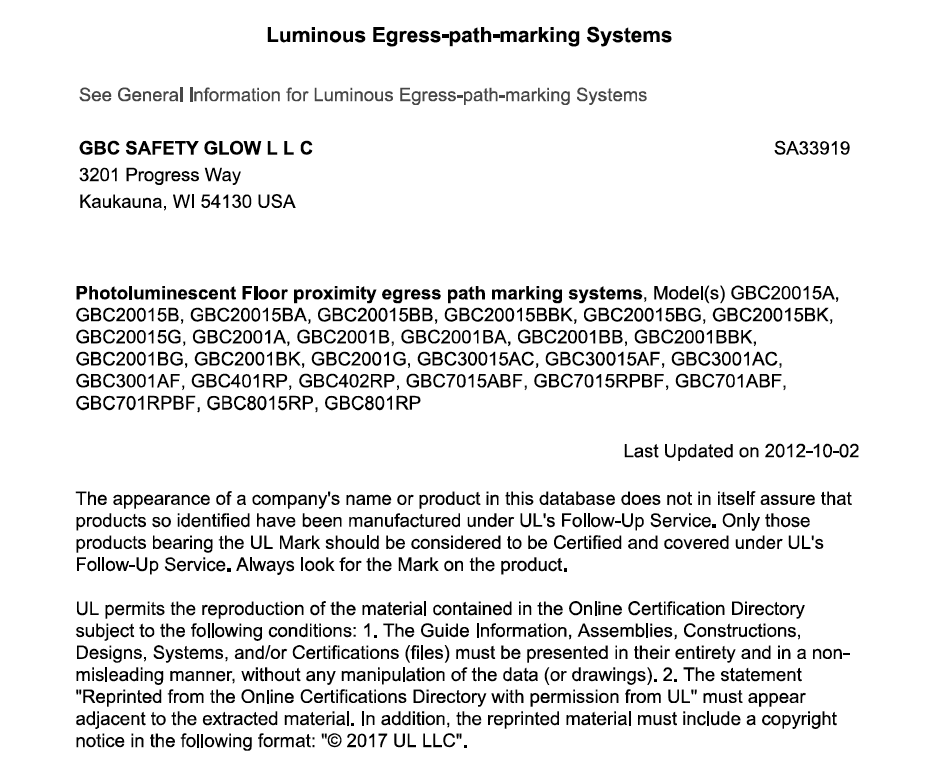

IBC and IFC 2009, 2012, and 2015 have introduced new egress system component requirements. Only quality rigid components meet the high safety evaluation standards set out in UL 1994 for photo-luminescent egress system components.

Tape for emergency egress is non-compliant with IBC/IFC 2009, 2012, and 2015 standards and is not code compliant with UL 1994 listings, however, many companies still utilize the old method of tape. This is unsafe! Tapes do not have the capacity to glow as bright or as long as the required rigid or semi-rigid components. After a little bit of wear, tape will get slippery, dirty, and start to peel off, unstick, and tear. Tape needs to be reapplied often and is not durable or made for long wear.

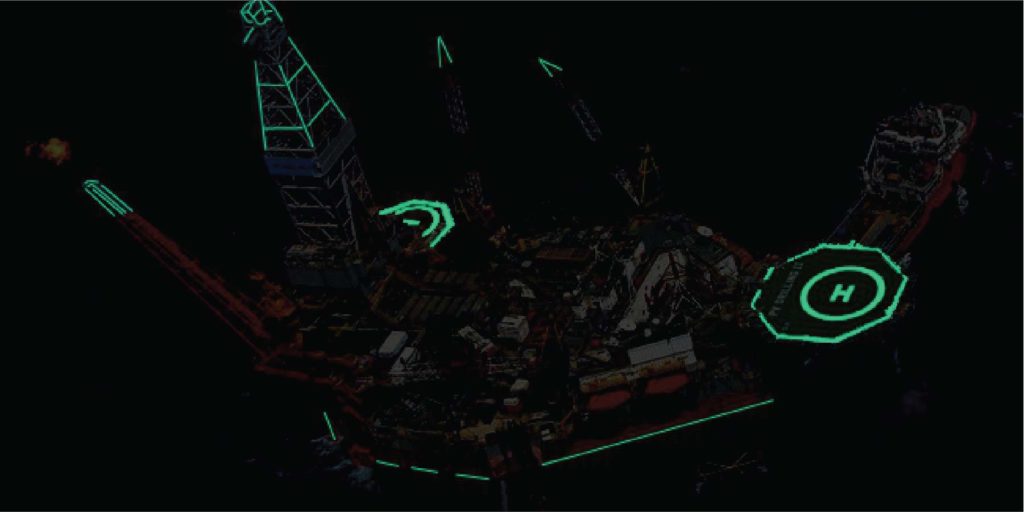

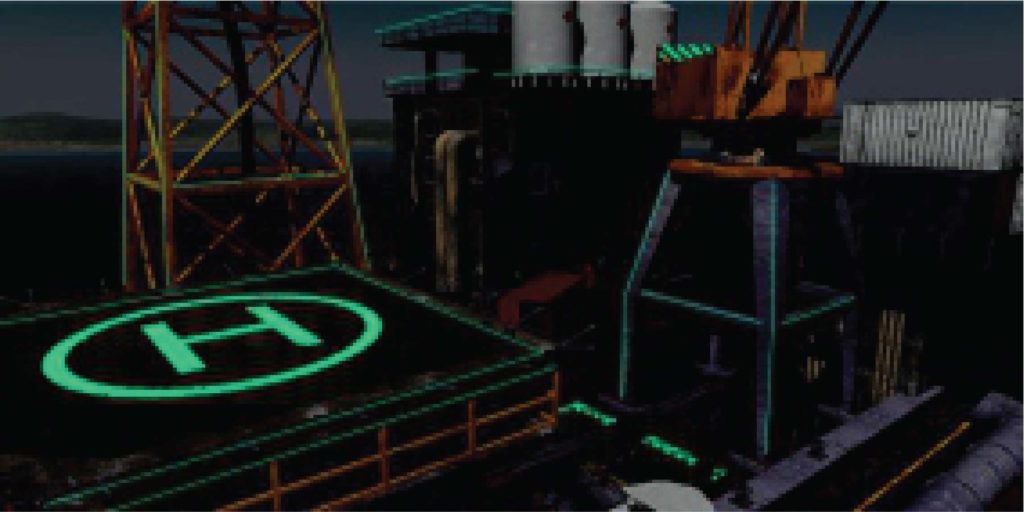

GBC has the code compliant answer for your emergency egress system needs.

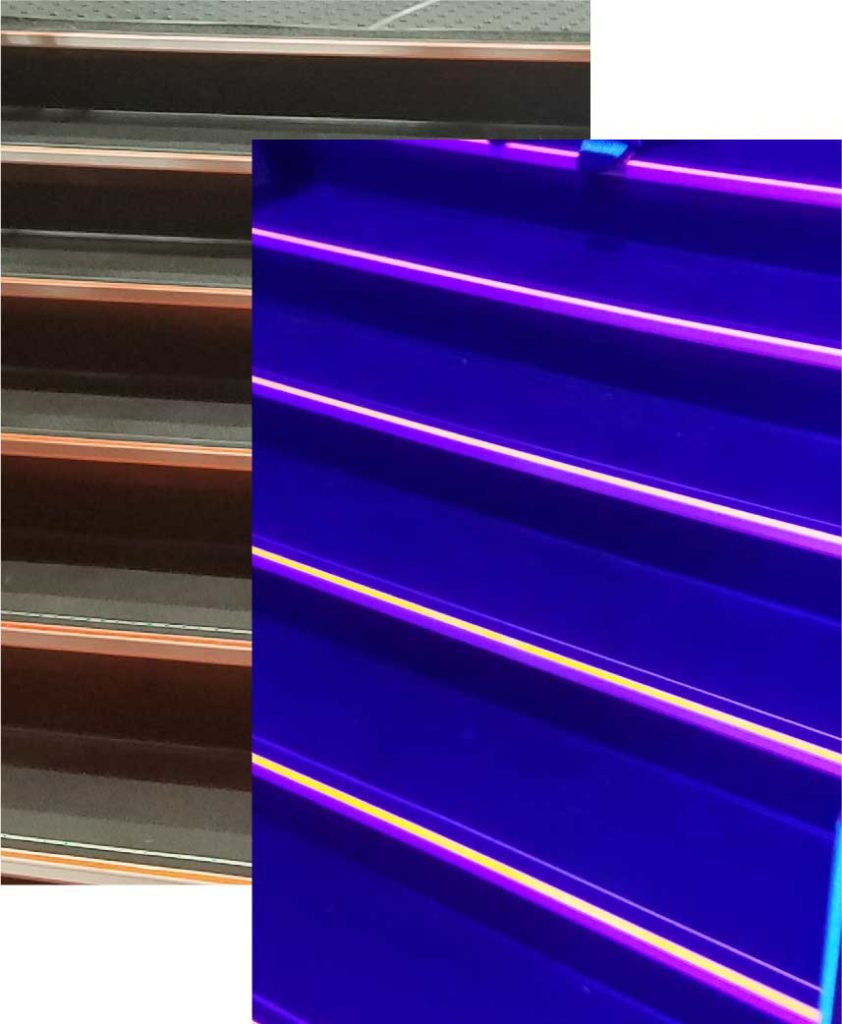

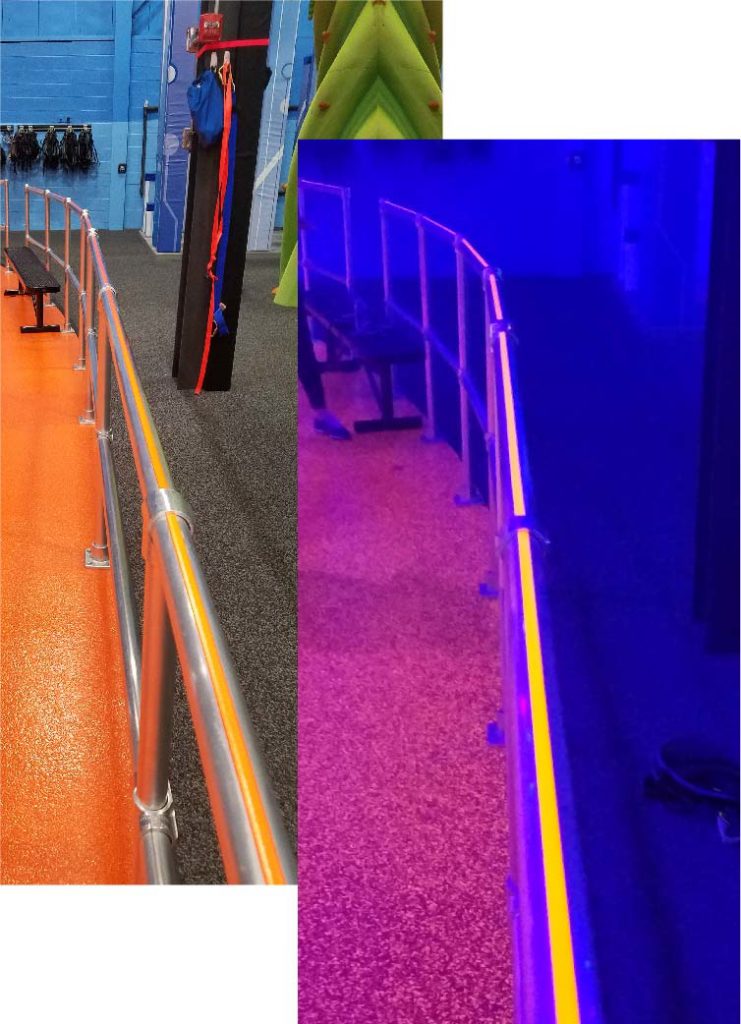

Instead of tape, use GBC Safety Glow’s Bull Nose Stair Treads. Constructed of extruded aluminum, the treads were built with durability and longevity in mind. Treads utilize proprietary polymer fusion technology and proprietary anti-skid black substrate with embedded aggregate that allows for heavy traffic and extended longevity. These treads hold up in ice, rain, or snow in any lighting conditions. Bull Nose Stair Treads have a wrap around edge that is ideal for use over carpet or for covering up rough edges to help the appearance of step damage. Stair tread is available in aluminum, bronze, black, and gold finish.